The efficiency of a transformer is defined as the ratio of its output power to its input power. Efficiency is influenced by factors such as the transformer design, core material, winding configuration, and load conditions. Transformers are designed to operate at high efficiency under normal operating conditions to minimise energy losses in power transmission and distribution systems. A higher efficiency indicates that a larger proportion of the input power is being transformed into useful output power while less is being lost as heat or other losses.

A notable fact about transformer efficiency is that modern transformers, especially those designed for high-voltage power transmission, often achieve efficiency levels exceeding 98%. This means that more than 98% of the electrical power input into the transformer is successfully transformed and delivered as output power, while a small percentage is lost as heat and other losses.

At Special Transformer, our commitment to advanced technology ensures that the transformers we manufacture not only meet but often surpass these high-efficiency benchmarks. We take pride in crafting transformers that embody the pinnacle of efficiency, providing reliable and sustainable solutions for power transmission needs.

An Introduction to the Efficiency of Transformer

Transformer efficiency is a measure of how effectively a transformer converts electrical power from the input (primary) side to the output (secondary) side. It is expressed as a percentage and indicates the ratio of useful output power to the total input power.

Efficiency in the context of a power transformer is quantified by the ratio of the output power to the input power, expressed as a percentage. It serves as a critical performance metric, reflecting how much of the supplied electrical energy is effectively transformed into usable output power. The quest for high efficiency is driven by the desire to minimise energy wastage and optimise the economic viability of power transmission and distribution systems.

At the core of the transformer’s functionality is the manipulation of a magnetic field generated by the primary coil, which induces a voltage in the secondary coil. The efficiency of the transformer is a measure of how effectively it can convert the input electrical power into usable output power. This efficiency is crucial in minimising power loss during the energy transfer process.

In the intricate dance of electromagnetic forces within a power transformer, the primary coil, energised by an alternating current, establishes a magnetic field in the transformer core. This magnetic field, in turn, induces a voltage in the secondary coil, facilitating the transfer of electrical energy. However, despite the transformer’s sophisticated design, it is not immune to losses. Various factors contribute to power losses within the transformer, including resistive losses in the conductors, eddy current losses in the core, and hysteresis losses resulting from the constant reversal of the magnetic field.

As a consequence, transformer manufacturers like Special Transformers continually strive to enhance design parameters, incorporate advanced materials to mitigate losses and boost overall efficiency. In the ever-evolving landscape of electrical engineering, achieving optimal efficiency in power transformers remains a perpetual pursuit, shaping the reliability and sustainability of global energy infrastructure.

Transformer efficiency calculation

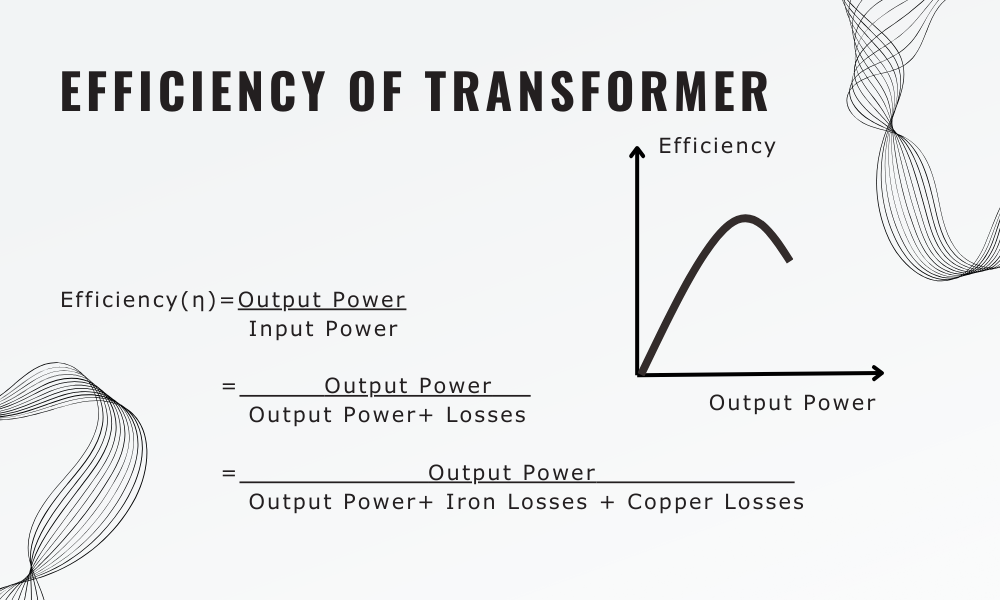

Transformer efficiency is calculated by comparing the output power to the input power and expressing the result as a percentage. The efficiency () can be determined using the formula:

=(Output Power/Input Power)×100%

Where:

- is the efficiency of the transformer,

- Output Power is the electrical power delivered to the load,

- Input Power is the electrical power supplied to the transformer.

This formula represents the ratio of usable output power to the total input power, providing a measure of how effectively the transformer converts electrical energy. Higher efficiency values indicate that a greater proportion of the input power is being transformed into useful output power, while lower efficiency values suggest more significant losses in the transformation process. In practical terms, transformer efficiency is a crucial factor in optimising energy transmission systems and reducing unnecessary power dissipation.

An Overview of the Transformer Losses

Within any electrical apparatus, ‘loss’ is quantified as the disparity between output and input power. Unlike dynamic devices, electrical transformers, being static instruments, do not incur mechanical losses such as friction or windage. Instead, transformers exclusively experience electrical losses, primarily attributed to copper and iron losses.

The primary culprits for losses in transformers are mentioned below:

Copper Losses:

Copper losses or Resistive losses, also known as I²R losses, occur due to the resistance of the transformer windings. The electrical current passing through the windings encounters resistance, leading to the generation of heat and energy loss.

Stray Losses:

Stray losses encompass losses in adjacent conductors, insulation, and other components not directly contributing to the transformer’s intended function. These losses arise due to factors such as proximity effects and capacitive coupling.

Hysteresis Losses:

Hysteresis loss stems from the reversal of magnetisation within the transformer’s core. This loss hinges on factors such as the frequency of magnetic reversals, the characteristics and quality of the iron used, and the degree of flux density.

Eddy Current Losses:

Eddy current loss occurs due to the circular currents induced in the conductive material of the transformer’s core, primarily in the laminated iron core. These circulating currents result in resistive heating and contribute to energy dissipation.

Iron Losses or Core Loses:

Core losses arise from eddy current and hysteresis losses, both contingent on the magnetic properties of the core material. These losses are collectively termed core losses or iron losses. Both contribute to the dissipation of energy in the form of heat.

Flux Losses:

In addition to the aforementioned losses, transformers also incur flux losses. These losses arise from the leakage flux, which occurs when not all the magnetic flux generated in the primary winding links with the secondary winding. Factors influencing flux losses include the load current, voltage, and the degree of magnetic coupling between the primary and secondary windings.

Understanding the interplay of these losses is crucial for achieving optimal power efficiency in transformers. While copper losses generate heat through the resistance of windings, iron losses transform electrical energy into heat within the core. Stray losses further compound the dissipation, emphasising the need for a comprehensive approach to minimise overall energy wastage.

Say goodbye to energy wastage!

Let’s focus on minimising transformer losses, addressing concerns such as leakage and maximising overall efficiency. Trust Special Transformers to provide you with transformers that go beyond the conventional, embodying the essence of the ideal transformer.

Improve Transformer Efficiency with Special Transformers!

At Special Transformer Australia, we specialise in the complete lifecycle of transformers – from wholesome design to precision manufacturing, smooth repair, and strategic upgrades with Certifications. Our transformers, including distribution transformers, are engineered to deliver maximum efficiency at full load, ensuring optimal performance even under demanding conditions.

- How is transformer efficiency calculated?

Transformer efficiency is calculated by dividing the output power by the input power and multiplying the result by 100 to get a percentage. Efficiency (%) = (Output Power / Input Power) * 100. - What factors affect transformer efficiency?

Factors influencing transformer efficiency include core material quality, winding resistance, load conditions, and design characteristics. Higher-quality materials and optimised designs generally contribute to higher efficiency. - What are the main types of losses affecting transformer efficiency?

The main types of losses are copper losses (I²R losses), stray losses, hysteresis losses, eddy current losses, iron losses (core losses), and flux losses. - Can transformer efficiency change under different load conditions?

Yes, transformer efficiency varies with load conditions. Transformers are typically most efficient when loaded close to their rated capacity. Efficiency may decrease at lighter or heavier loads. - Why is high transformer efficiency important?

High transformer efficiency is crucial for minimising energy wastage and reducing operational costs. It also contributes to a more sustainable and environmentally friendly power distribution system. - Are there industry standards for transformer efficiency?

Yes, industry standards, such as those set by organisations like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), provide guidelines for transformer efficiency. - How do modern transformers achieve high-efficiency levels?

Modern transformers achieve high efficiency through advancements in core materials, improved winding designs, and enhanced manufacturing processes. High-voltage power transmission transformers often exceed 98% efficiency. - How does transformer efficiency impact energy conservation?

Transformer efficiency directly influences the amount of electrical energy wasted during power transmission. Higher efficiency means less energy loss, contributing to overall energy conservation efforts and reduced environmental impact.

With two decades of expertise, Special Transformer is your trusted partner for manufacturing transformers. For solutions that prioritise efficiency, reliability, and sustainability, reach out to us.